图1 IL-DLLME技术近7年出版文章数目趋势

Fig.1The annual number of publications regarding IL-DLLME in the last seven years

张 琰 1,2,3,4,5,张耀海 2,3,4,5,焦必宁 1,2,3,4,5,*

(1.西南大学园艺园林学院,重庆 400715;2.国家柑桔工程技术研究中心,中国农业科学院柑桔研究所,重庆 400712;3.农业部柑橘产品质量安全风险评估实验室,重庆 400712;4.农业部柑桔及苗木质量监督检验测试中心,重庆 400712;5.柑桔学重庆市市级重点实验室,重庆 400712)

摘要:离子液体以其蒸汽压低、热稳定性好、良好的溶解性和可设计性等特性在萃取分离领域应用广泛。本文就离子液体性质、离子液体-分散液液微萃取模式进行介绍,重点综述该项技术在食品和环境污染物检测中的最新应用进展,并对其发展前景进行展望。

关键词:离子液体;分散液液微萃取;食品;环境污染物;应用

样品前处理是分析检测的关键步骤之一。近年来,样品前处理方法正朝着简单化、节约化和微型化方向发展。2006年,Rezaee等 [1]首次提出分散液液微萃取技术(dispersive liquid-liquid microextraction,DLLME),该技术集采样、萃取和浓缩于一体,具有操作简单、快速、成本低、富集效率高、有机溶剂用量少等特点。但传统的DLLME通常使用四氯化碳、氯仿等卤代烃作为提取溶剂,这些溶剂毒性大且对环境不友好。

离子液体(ionic liquid,IL),也称室温离子液体(room-temperature ionic liquid,RTIL),具有低蒸汽压、不易燃、热稳定性好等性质。离子液体代替传统的有机溶剂可以避免挥发带来的环境污染问题,因此被誉为“绿色溶剂”。

将离子液体和分散液液微萃取技术结合,可以充分利用二者优点,形成集萃取、浓缩于一体的操作简便、快速、高回收率、前处理微型化的绿色环保新方法。2008年,Zhou Qingxiang [2]和Baghdadi [3]等最早将离子液体和分散液液微萃取技术结合,形成了离子液体-分散液液微萃取技术(ionic liquid-based dispersive liquid-liquid microextraction,IL-DLLME),并分别应用于环境样品中有机磷农药和Hg元素的分析检测。此后,关于ILDLLME技术检测有机化合物及元素含量的研究相继出现(图1)。本文首先简要介绍离子液体性质,分析比较IL-DLLME不同模式间的优缺点,就其在食品和环境污染物检测中的应用进行综述,以期为IL-DLLME的发展提供参考。

图1 IL-DLLME技术近7年出版文章数目趋势

Fig.1The annual number of publications regarding IL-DLLME in the last seven years

1.1 分散液液微萃取的原理

分散液液微萃取技术的原理是将混有微量萃取剂的分散剂快速注入样品溶液,萃取剂在分散剂的作用下以细小液滴的形式均匀分散在样品溶液中,形成样品溶液-分散剂-萃取剂的三元乳浊液体系。由于萃取剂和样品溶液有较大的接触面积,目标物在二者之间快速达到萃取平衡,离心、冷却或凝固后,目标物被富集在离心管底部微量沉淀相中,注射器取出后即可用于仪器分析。该方法可以在较短的萃取时间内获得较高富集倍数和回收率,其具体操作过程如图2所示。

图2分散液液微萃取的操作过程

Fig.2Flow chart of dispersive liquid-liquid microextraction

对分散液液微萃取而言,萃取剂和分散剂种类的选择是提高萃取效率的关键。因此,萃取剂应满足密度比水大、且与目标物性质匹配、有良好的色谱行为。常用的萃取剂主要有氯仿、氯苯、四氯化碳、四氯乙烯、二氯甲烷、三氯乙烷等。而分散剂种类的选择要满足同时溶于样品溶液和萃取剂,才能保证可在样品溶液中分离萃取剂 液滴。常用的分散剂主要有甲醇、乙腈、丙酮、四氢呋喃等。

1.2 离子液体的性质

离子液体最突出的优点包括蒸汽压低、热稳定性好、黏度可调等。1)溶解性是离子液体的一个重要物理特性,可以通过阴离子或烷基链长度的改变来对这一特性进行调控;2)熔点由离子对称性、范德华力、氢键和离子电荷分布的均匀程度决定,比如用无机阳离子代替非对称的有机阳离子可以显著增大离子液体的熔点;3)离子液体的表面张力与阴、阳离子结构有关,随着与其结合的烃基链长度的减小而增大。4)离子液体的热稳定性主要取决于阴、阳离子,而阴离子对热稳定性的影响更大;5)与传统有机溶剂相比,离子液体具有较高的黏度,通常是有机溶剂黏度的2~3 个数量级,通过升高温度可以降低离子液体黏度。此外,离子液体黏度还由分子间作用力(库伦力、范德华力)决定 [4]。

此外,离子液体的毒理特性也是影响其应用的重要因素之一,近年来也有很多关于离子液体毒性在水生生态系统和微生物等方面的研究 [5]。研究结果表明离子液体并非全部具有低毒性,其毒性高低与阳离子是否为芳香环、芳香环碳数及阳离子上取代烃链的长度有关。一般阳离子为芳香烃的离子液体毒性高于阳离子为非芳香烃的离子液体,六元环毒性大于五元环,较短的烃基取代链比长链毒性小;阴离子种类对离子液体毒性影响更为复杂,需要更深入调查研究 [6-7]。

目前主要研究的离子液体由不对称的阳离子,如咪唑类、吡咯类、吡啶类、季铵盐类及季磷盐类和无机或有机阴离子构成,如[BF 4] -、[PF 6] -、Cl -、Br -、[CF 3SO 3] -等 [8-9]。代表性的离子液体有1-丁基-3-甲基咪唑六氟磷酸盐([C 4MIM][PF 6])、1-己基-3-甲基咪唑六氟磷酸盐([C 6MIM][PF 6])和1-辛基-3-甲基咪唑六氟磷酸盐([C 8MIM][PF 6]),多用于环境及食品污染物的检测。因此,通过离子液体理化性质的改变可以扩大其应用范围,对其理化性质分析方法的研究受到普遍重视。

1.3 离子液体-分散液液微萃取的模式

IL-DLLME联用技术以IL代替传统的含氯有机试剂作为萃取剂,在分散剂的作用下扩散并进行有序排列,形成IL-样品溶液-分散剂的三元溶剂萃取体系。以咪唑类IL为例:亲水性咪唑阳离子指向外部水体系,疏水性烷基链聚集构成疏水内核,不同极性的目标物分布于烷基链不同部位或进入疏水内核从而被IL萃取。目前,除了传统IL-DLLME,研究人员也对这一方法进行了一系列改进,如当萃取剂密度低于水时使用涡旋或超声波提高萃取效率 [10-11],与目标物衍生相结合 [12]。Trujillo-Rodríguez等 [13]总结了近年来IL-DLLME的应用。本文将IL-DLLME主要分为3 种模式:传统离子液体-分散液液微萃取,温控、超声波、涡旋或微波辅助离子液体-分散液液微萃取,原位离子液体-分散液液微萃取。

传统IL-DLLME是3 种模式中最为简单的模式。在萃取剂-样品溶液-分散剂三相混合后,无需外界能量如温控、超声波等加速萃取,手动搅拌或振荡后离心即可将含有目标物的离子液滴从水相中分离。但传统IL-DLLME也存在难以应对多种目标物、萃取效率低等缺点,因此研究人员开发了温控辅助(temperaturecontrolled-assisted,TCA)、超声波辅助(ultrasoundassisted,UA)、涡旋辅助(vortex-assisted,VA)和微波辅助(microwave-assisted,MA) IL-DLLME模式。这些模式需借助外界能量对含有目标物的样品进行加热、超声波、涡旋或微波,提高离子液体在样品溶液中的溶解度,增大与目标物的接触面积,从而提高萃取效率,并且可减缓萃取过程中的有机反应。原位离子液体-分散液液微萃取(in situ IL-DLLME),又称基于离子液体的原位溶剂形成微萃取(ionic liquid-in situ solvent formation microextraction,IL-ISFME),该模式采用亲水性离子液体作为萃取剂,一种阴离子交换剂和其发生置换反应生成新的疏水性离子液体,集萃取、置换反应、形成离子液体沉淀相于一体,大大缩短了萃取时间。目前,采用该模式的研究中基本没有使用分散剂,通常亲水性离子液体和阴离子交换剂保持1∶1的比例。表1将3 种模式进行了对比,以下将就IL-DLLME在农药残留、食品添加剂、元素等其他化学污染物检测中的应用作简要综述。

表1 离子液体-分散液液微萃取的3种模式3

Table1Modes of IL-DLLMEDLLME

注:—.文献中未提及。下同。

模式萃取剂分散剂萃取方式冰浴传统IL-DLLME疏水性离子液体(萃取金属元素时需加入螯合剂、离子对试剂)有机溶剂、疏水性离子液体——温控、超声波、涡旋、微波辅助IL-DLL ME疏水性离子液体(萃取金属元素时需加入螯合剂)有机溶剂、疏水性离子液体、表面活性剂能量(搅拌、加热、超声波、微波、涡旋)有时原位IL-DLLME亲水性离子液体(萃取金属元素时需加入螯合剂)一般不用或用阴离子交换剂能量(搅拌、加热、超声波、微波、涡旋)有时

2.1 IL-DLLME在农兽药残留检测中的应用

近年来,随着我国居民生活水平的提高,农兽药残留造成的环境及农产品安全事故频发,为有效控制农兽药残留污染,发展简单、快速、可靠和应用范围广的检测方法显得尤为重要。

Zhou Qingxiang等 [2]最早提出将TCA-IL-DLLME结合高效液相色谱-紫外检测(high performance liquid chromatography-ultra violet,HPLC-UV)应用到环境水样中有机磷杀虫剂(甲基对硫磷和辛硫磷)的检测:50 μL离子液体[C 6MIM][PF 6]和10 mL水混合后,80 ℃水浴加热,冰浴30 min,离心后取沉淀上机分析;在优化条件下,该方法的富集倍数为50,检出限为0.17~0.29 ng/mL,回收率为88.2%~103.6%。该方法简单、有效,为今后IL-DLLME开辟了新视角。Zhang Jiaheng等 [14]利用UA-IL-DLLME结合HPLC-二极管阵列检测器(diode array detector,DAD)技术检测蜂蜜中4 种拟除虫菊酯:以离子液体[C 8MIM][PF 6]为萃取剂,甲醇为分散剂,富集倍数高达506~515 倍,回收率为101.2%~103.0%;同时第一次提出将UA-IL-DLLME与传统IL-DLLME和TCA-IL-DLLME进行了比较,结果表明UA-IL-DLLME的萃取效率最高,接近100%。

IL-DLLME技术中,多使用有机试剂作为分散剂 。最近的研究已将离子液体作为分散剂。Zhao Rusong等 [15]以离子液体[C 8MIM][PF 6]为萃取剂,[C 4MIM][BF 4]为分散剂,利用IL-DLLME结合HPLC-UV技术检测了水样中苄氯菊酯和联苯菊酯,优化条件下检出限为0.28~0.83 μg/L,回收率为84%~114%。有机试剂的减少,使IL-DLLME技术更加环保,此方法可能成为今后前处理方法研究的新方向。

最初的IL-DLLME技术仅适用于简单基质(以水体为代表),近年来,此技术也逐渐应用于复杂基质中,比如果蔬和土壤。Ravelo-Pérez等 [16]以[C 6MIM][PF 6]为萃取剂,甲醇为分散剂,并与HPLC-DAD结合测定了香蕉中8 种农药残留,优化条件下其检出限满足该8 种农药农残检测标准。2012年,Zhang Lijin等 [17]采用VA-IL-DLLME模式结合HPLC-UV检测苹果、梨中6 种有机磷农药,以[C 8MIM][PF 6]为萃取剂,甲醇为分散剂,优化条件下富集倍数大于300,检出限为0.061~0.73 μg/L,回收率为69.8%~109.1%。

离心在传统DLLME中是必不可少但又被认为是最耗时的步骤,通过离心可将含有目标物的萃取剂沉淀至离心管底部。最近有研究建议将磁性纳米粒子 [18](magnet ic nanoparticles,MNPs)应用到IL-DLLME技术中,利用MNPs的超顺磁性和较大接触面积等优点,可以减少萃取剂时间,使处理自动化。Zhang Jiaheng等 [19]提出MR(magnetic retrieval)-IL-DLLME,并结合HPLC-可变波长检测器(automated variable-wavelength detector,VWD)检测环境水样中5 种苯甲酰脲杀虫剂:以离子液体[C 6MIM][PF 6]为萃取剂,乙腈为分散剂,萃取后加入磁性纳米粒子Fe 3O 4,将离子液体从样品溶液中直接分离,从而代替了传统的离心操作;在优化条件下富集倍数高达261~302 倍,检出限为0.05~0.15 μg/L,回收率为79.8%~91.7%。该方法快速、高效、绿色,适合大批量样品的快速检测。

IL-DLLME技术同样适用于兽药残留检测。Qin Hui等 [20]首次提出离子液体涡旋辅助协同微萃取(ionic liquid supported vortex-assisted synergic microextraction,ILSVA-SME)结合HPLC-UV检测水样中微量糖皮质激素:以离子液体[C 4MIM][PF 6]作为萃取剂,表面活性剂聚乙二醇辛基苯基醚(Triton X-100)作为分散剂;在优化条件下,富集倍数达99.85,检出限为0.23~1.30 μg/L,回收率为97.24%~102.2%。该研究使用非离子表面活性剂为分散剂代替了传统有机试剂,减少有毒试剂消耗,研究组还将该方法与传统方法固相萃取(solid phase extraction,SPE)、固相微萃取(solidphase micro-extraction,SPME)和浊点萃取(cloud point extraction,CPE)进行了比较,其萃取时间短、效率高、且无需加热的特点使其在对同类物质的检测中具有潜在应用价值。

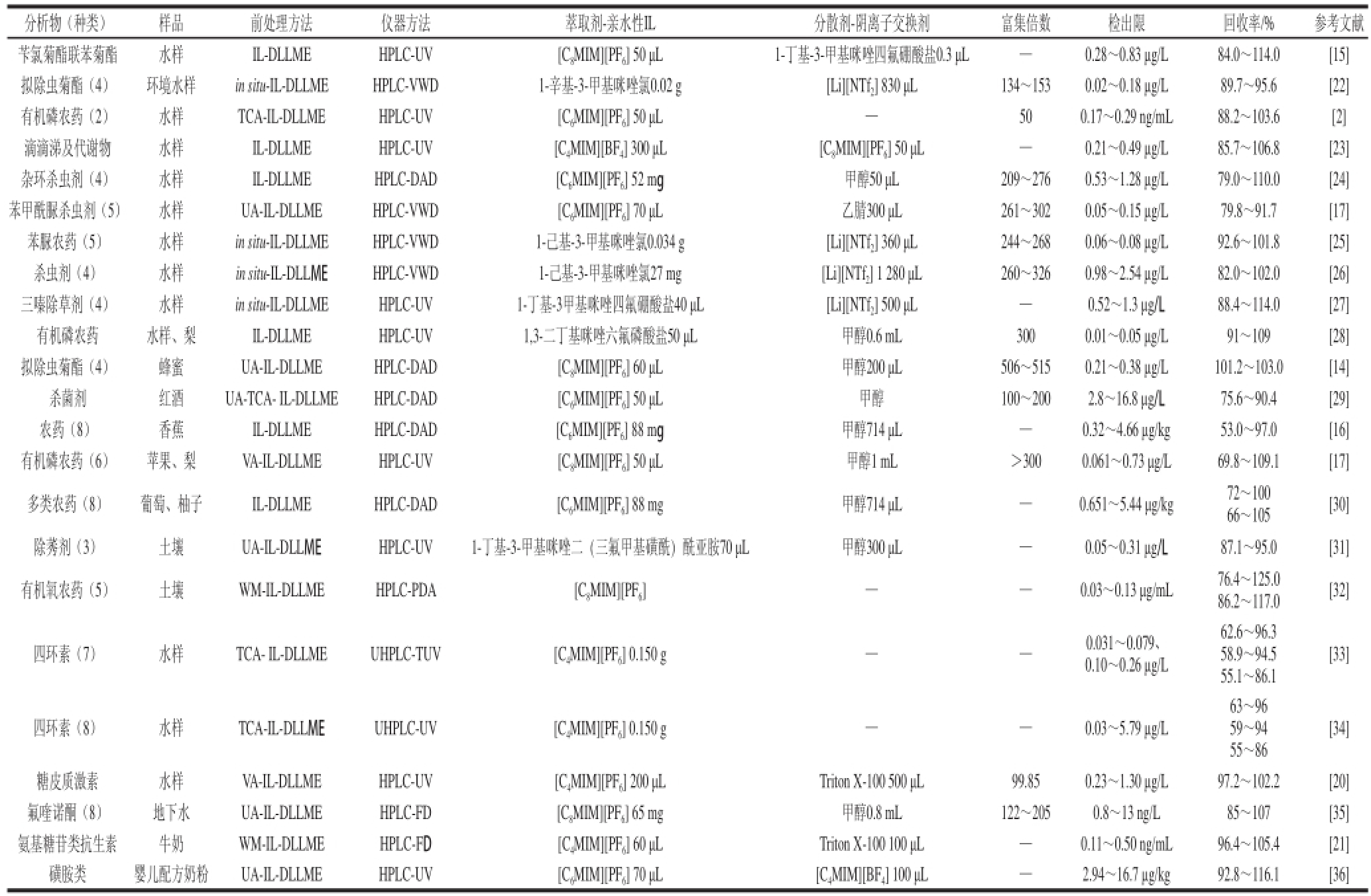

表2IL-DLLME在农兽药残留检测中的应用

Table2Application of IL-DLLME in the analysis of pesticide and veterinary drug residues

分析物(种类)样品前处理方法仪器方法萃取剂-亲水性IL分散剂-阴离子交换剂富集倍数检出限回收率/%参考文献苄氯菊酯联苯菊酯水样IL-DLLMEHPLC-UV[C 8MIM][PF 6] 50 μL1-丁 基-3-甲基咪唑四氟硼酸盐0.3 μL—0.28~0.83 μg/L84.0~114.0[15]拟除虫菊酯(4)环境水样in situ-IL-DLLMEHPLC-VWD1-辛基-3-甲基咪唑氯0.02 g[Li][NTf 2] 830 μL134~1 530.02~0.18 μg/L89.7~95.6[22]有机磷农药(2)水样TCA-IL-DLLMEHPLC-UV[C 6MIM][PF 6] 50 μL—500.17~0.29 ng/mL88.2~103.6[2]滴滴涕及代谢物水样IL-DLLMEHPLC-UV[C 4MIM][BF 4] 300 μL[C 8MIM][PF 6] 50 μL—0.21~0.49 μg/L85.7~106.8[23]杂环杀虫剂(4)水样IL-DLLMEHPLC-DAD[C 6MIM][PF 6] 52 mg甲醇50 μL209~2760.53~1.28 μg/L79.0~110.0[24]苯甲酰脲杀虫剂(5)水样UA-IL-DLLMEHPLC-VWD[C 6MIM][PF 6] 70 μL乙腈300 μL261~3020.05~0.15 μg/L79.8~91.7[17]苯脲农药(5)水样in situ-IL-DLLMEHPLC-VWD1-己基-3-甲基咪唑氯0.034 g[Li][NTf 2] 360 μL244~2680.06~0.08 μg/L92.6~101.8[25]杀虫剂(4)水样in situ- IL-DLLMEHPLC-VWD1-己基-3-甲基咪唑氯27 mg[Li][NTf 2] 1 280 μL260~3260.98~2.54 μg/L82.0~102.0[26]三嗪除草剂(4)水样in situ-IL-DLLMEHPLC-UV1-丁基-3甲基咪唑四氟硼酸盐40 μL[Li][NTf 2] 500 μL—0.52~1.3 μg/L88.4~114.0[27]有机磷农药水样、梨IL-DLLMEHPLC-UV1,3-二丁基咪唑六氟磷酸盐50 μL甲醇0.6 mL3000.01~0.05 μg/L91~109[28]拟除虫菊酯(4)蜂蜜UA-IL-DLLMEHPLC-DAD[C 8MIM][PF 6] 60 μL甲醇200 μL506~5150.21~0.38 μg/L101.2~103.0[14]杀菌剂红酒UA-TCA- IL-DLLMEHPLC-DAD[C 6MIM][PF 6] 50 μL甲醇100~200 2.8~16.8 μg/L75.6~90.4[29]农药(8)香蕉IL-DLLMEHPLC-DAD[C 6MIM][PF 6] 88 mg甲醇714 μL—0.32~4.66 μg/kg53.0~97.0[16]有机磷农药(6)苹果、梨VA-IL-DLLMEHPLC-UV[C 8MIM][PF 6] 50 μL甲醇1 mL>3000.061~0.73 μg/L69.8~109.1[17]多类农药(8)葡萄、柚子IL-DLLMEHPLC-DAD[C 6MIM][PF 6] 88 mg甲醇714 μL—0.651~5.44 μg/kg72~100 66~105[30]除莠剂(3)土壤 UA-IL-DLLMEHPLC-UV1-丁基-3-甲基咪唑二(三氟甲基磺酰)酰亚胺70 μL甲醇300 μL—0.05~0.31 μg/L87.1~95.0[31]有机氧农药(5)土壤WM-IL-DLLMEHPLC-PDA[C 8MIM][PF 6]——0.03~0.13 μg/mL76.4~125.0 86.2~117.0[32]四环素(7)水样TCA- IL-DLLMEUHPLC-TUV[C 4MIM][PF 6] 0.150 g——0.031~0.079、0.10~0.26 μg/L四环素(8)水样 TCA-IL-DLLMEUHPLC-UV[C 4MIM][PF 6] 0.150 g——0.03~5.79 μg/L 62.6~96.3 58.9~94.5 55.1~86.1 63~96 59~94 55~86 [33] [34]糖皮质激素水样VA-IL-DLLMEHPLC-UV[C 4MIM][PF 6] 200 μLTriton X-100 500 μL99.850.23~1.30 μg/L97.2~102.2[20]氟喹诺酮(8)地下水UA-IL-DLLMEHPLC-FD[C 8MIM][PF 6] 65 mg甲醇0.8 mL122~2050.8~13 ng/L85~107[35]氨基糖苷类抗生素牛奶WM-IL-DLLME HPLC-FD[C 4MIM][PF 6] 60 μLTriton X-100 100 μL—0.11~0.50 ng/mL96.4~105.4[21]磺胺类婴儿配方奶粉UA-IL-DLLMEHPLC-UV[C 6MIM][PF 6] 70 μL[C 4MIM][BF 4] 100 μL—2.94~16.7 μg/kg92.8~116.1[36]

IL-DLLME也可与衍生方法结合。Xu Xu等 [21]首次提出IL-MASI-DLLME(IL-based microwave-assisted surfactantimproved DLLME)结合HPLC一步衍生、萃取检测牛奶中氨基糖苷类抗生素:以离子液体[C 4MIM][PF 6]为萃取剂,表面活性剂Triton X-100为分散剂,氯甲酸-9-芴基甲酯(9-fluorenylmethyl chloroformate,[FMOC][Cl])为衍生剂,180 W条件下微波60 s;在优化条件下检出限为0.11~0.50 μg/L,回收率为96.4%~105.4%,技术指标均满足目标物检测要求。使用表面活性剂,一步衍生、萃取、预浓缩,减少有机试剂使用量,缩短萃取时间,提高了萃取效率。

表2为对近年来IL-DLLME在农兽药残留检测中的应用所进行的总结。

2.2 IL-DLLME在真菌毒素检测中的应用

食品中常见真菌毒素如黄曲霉毒素、脱氧雪腐镰刀菌烯醇、展青霉素、赭曲霉毒素A等,这些毒素及其次生代谢物重者可导致人体器官损害、功能衰竭。目前,DLLME技术主要应用于酒、谷物和苹果汁中真菌毒素的检测,但应用IL-DLLME技术检测食品及环境中真菌毒素的研究仅有少量报道。Arroyo-Manzanares等 [37]首次提出IL-DLLME结合毛细管液相色谱-荧光检测器分析酒中赭曲霉素A:以离子液体[C 6MIM][PF 6]为萃取剂,甲醇为分散剂,在优化条件下检出限为5.2 ng/L,回收率为88.7%~94.2%。同时 ,将该方法同QuEChERS(Quick, Easy, Cheap, Effective, Rugged and Safe)进行对比,结果表明,IL-DLLME回收率较好,但精密度和重现性均 不及QuEChERS。

Mohammadi等 [38]改进了IL-DLLME,首次将酶辅助萃取(enzyme-assisted extraction,EAE)结合IL-DLLME-HPLC技术用于检测苹果汁中展青霉素:以离子液体[C 6MIM][PF 6]为萃取剂,甲醇为分散剂,在优化条件下,富集倍数达162,检出限为0.15 ng/g,回收率为89%。该方法简单、快速、灵敏并且降低基质效应,为这一领域内物质的研究提供了有效的新方法。

2.3 IL-DLLME在食品添加剂检测中的应用

食品添加剂主要有抗氧化剂、着色剂、护色剂、漂白剂等,可以改善食品色、香、味等品质,提高食品营养价值,并且防腐保鲜促进消费。但长期或过量食用会对人体产生潜在副作用。因此有必要建立针对此类物质的简单、可靠、快速的检测方法。表3列出了IL-DLLME在食品添加剂检测中的具体应用。Yang Peng等 [39]以离子液体[C 8MIM][PF 6]为萃取剂,乙腈为分散剂,应用传统IL-DLLME结合HPLC-UV分析了煎饼中4 种防腐剂(对羟基苯甲 酸甲酯、羟苯乙酯、对羟基苯甲酸丙脂、对羟基苯甲酸丁酯),结果满足食品中防腐剂检测要求。

Guo Jingbo等 [40]建立了TCA-IL-DLLME结合紫外分光光度计检测8 种食品和化妆品中亮蓝的新方法,以离子液体1-癸基-3-丁基咪唑六氟磷酸盐([C 10MIM][PF 6])为萃取剂,无需分散剂,优化条件下,检出限为0.34 n g/L,回收率为97.7%~103.4%。最近,Wu Hao等 [41]通过传统IL-DLLME结合HPLC-UV技术检测软饮料、糖果两种基质中6 种合成食品着色剂,以离子液体[C 8MIM][PF 6]为萃取剂,回收率为95.8%~104.5%。

表3IL-DLLME在真菌毒素和食品添加剂检测中的应用

Table3Application of IL-DLLME in the analysis of fungaltoxin and food additives

分析物(种类)样品前处理方法仪器方法萃取剂-亲水性IL分散剂-阴离子交换剂富集倍数检出限回收率/%参考文献展青霉素苹果汁EAE- IL-DLLMEHPLC-UV[C 6MIM][PF 6] 80 μL甲醇600 μL1620.15 ng/g89.0[38]赭曲霉毒素A酒IL-DLLMECapillary HPLC-LIF[C 6MIM][PF 6] 100 mg甲醇700 μL—5.2 ng/L88.7~94.2[37]刚果红水样IL-DLLMEFiber optic spectrograph[C 4MIM][Tf 2N] 90~400 mg丙酮500 μL——>95[45]增塑剂(5)水样WM- IL-DLLMEHPLC-UV[C 4MIM][PF 6] 110 μL甲醇0.4 μL—0.71~1.94 μg/L85.2~103.3[42]增塑剂(6)酒精饮料IL-DLLMEHPLC-DAD[C 8MIM][PF 6] 160 μL——3.1~4.2 ng/mL 1.5~2.2 ng/mL 88.5~103.5 91.6~104.6[43]合成着色剂(6)软饮料、糖果 IL-DLLMEHPLC-UV[C 8MIM][PF 6] 350 μL无—0.015~0.32 ng/mL95.8~104.5[41]亮蓝食品、化妆品TCA- IL-DLLMEUV-visible spectroscopy[C 10MIM][PF 6]无—0.34 μg/L97.7~103.4[40]柠檬黄、亮蓝食品TCA- IL-DLLMEUV-spectroscopy1-辛基-3-甲基咪唑四氟硼酸盐350 μL无—6.60 μg/L 0.84 μg/L 96~99 97~105[46]苏丹红、邻苯二甲酸酯(8)调味品IL-DLLMEHPLC-DAD[C 6MIM][PF 6] 30 μL乙腈1 mL4510.09~1.01 μg/L70~120[44]防腐剂(4)煎饼 IL-DLLMEHPLC-UV[C 8MIM][PF 6] 0.1 mL乙腈0.1 mL—1.0~1.5 ng/g 60.1~79.5[39]

近年来,增塑剂和工业染料等食品污染物冒充食品添加剂违法滥用危害人类健康,造成恶劣影响,研究人员对此进行了相关研究 [42-44]。Wang Ruoyu等 [42]建立微波辅助IL-DLLME-HPLC方法测定水样中5 种增塑剂:以离子液体[C 4MIM][PF 6]为萃取剂,甲醇为分散剂,回收率为85.2%~103.3%。随后,Ho等 [44]首次报道了应用IL-DLLME-HPLC-DAD快速筛查油状和固体调料中邻苯二甲酸酯增塑剂、苏丹红等8 种污染物残留的方法,以离子液体[C 6MIM][PF 6]为萃取剂,乙腈为分散剂,同其他报道的方法有所不同,采用装有惰性聚合熔块的固相萃取多孔墨盒,集过滤、溶剂混合、相分离于一步,在优化条件下,富集倍数高达451,回收率为70%~120%。该法具有操作简单、超高通量、低溶剂消耗、高灵敏度等特点,可应用于多种食品添加剂的快速筛查。

2.4 IL-DLLME在元素检测中的应用

由于工业排放、交通尾气和生活垃圾等因素产生的重金属元素对环境和人类造成污染。IL-DLLME技术也可应用到这类元素的检测中,从表4可以看出,已报道的方法多与火焰原子吸收(flame atomic absorption spectrometry,FAAS)、电热原子吸收(electrothermal atomic absorption spectrometry,ETAAS)和石墨炉原子吸收(graphite furnace atomic absorption spectrometry,GFAAS)联用。Baghdadi等 [3]提出冷诱导聚合微萃取(cold-induced aggregation microextraction,CIAME)结合分光光度法检测水样中Hg 2+,该方法加入两种离子液体[C 6MIM][PF 6](萃取剂)和1-己基-3-甲基咪唑N-[(三氟代甲基)磺酰基]-1,1,1-三氟代-甲烷磺酰胺([C 6MIM] [Tf 2N]),可以大大降低萃取剂在盐溶液中的溶解度。优化后该方法的回收率为97.5%~100.4%,适用于高盐溶液中Hg 2+的检测,并且避免了萃取剂的溶解。

López-García等 [47]采用原位IL-DLLME-ETAAS技术测定了水样中Cr 3+和Cr 6+,以亲水性离子液体[C 8MIM][Cl]为萃取剂,吡咯烷二硫代氨基甲酸铵(ammonium pyrrolidinedithiocarbamate,APDC)为螯合剂,优化实验条件下,该方法检出限为2 ng/L,回收率为95%~104%,富集倍数为300。Absalan等 [48]以离子液体[C 6MIM][PF 6]为萃取剂,利用温控辅助萃取,并与GFAAS结合测定水样中纳米数量级的Ag +。优化后测得富集倍数为120,检出限为5.2 ng/L,回收率为96.1%~104.1%,同其他方法相比,该方法富集倍数高,检出限低。

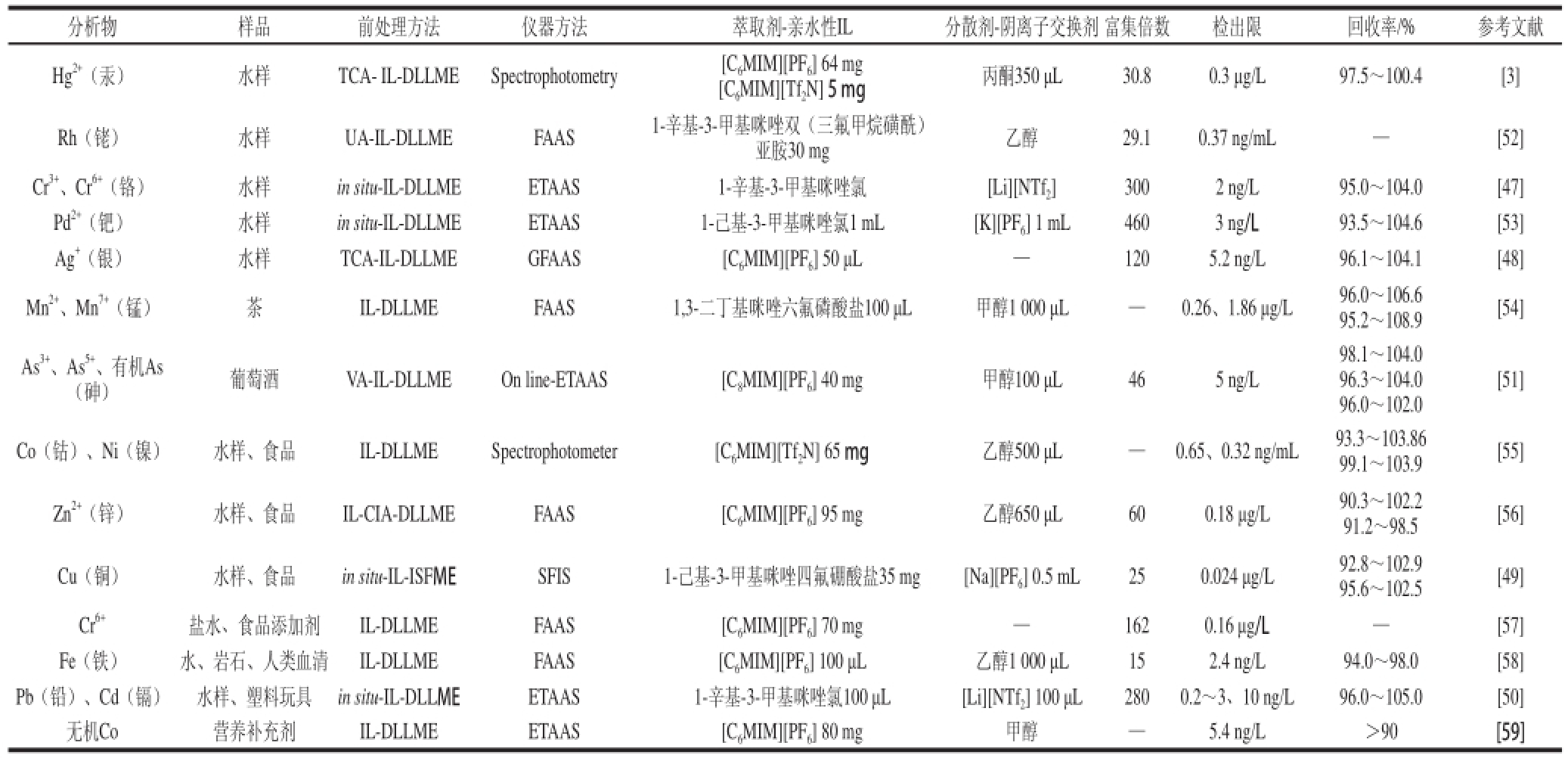

表4 IL-DLLME在元素检测中的应用

Table4Application of IL-DLLME in the analysis of elements

分析物样品前处理方法仪器方法萃取剂-亲水性IL分散剂-阴离子交换剂富集倍数检出限回收率/%参考文献Hg 2+(汞)水样TCA- IL-DLLMESpectrophotometry[C 6MIM][PF 6] 64 mg [C 6MIM][Tf 2N] 5mg丙酮350 μL30.80.3 μg/L97.5~100.4[3] Rh(铑)水样UA-IL-DLLMEFAAS1-辛基-3-甲基咪唑双(三氟甲烷磺酰)亚胺30 mg乙醇29.10.37 ng/mL—[52] Cr 3+、Cr 6+(铬)水样in situ-IL-DLLMEETAAS1-辛基-3-甲基咪唑氯[Li][NTf 2]3002 ng/L95.0~104.0[47] Pd 2+(钯)水样in situ-IL-DLLMEETAAS1-己基-3-甲基咪唑氯1 mL[K][PF 6] 1 mL4603 ng/L93.5~104.6[53] Ag +(银)水样TCA-IL-DLLMEGFAAS[C 6MIM][PF 6] 50 μL—1205.2 ng/L96.1~104.1[48] Mn 2+、Mn 7+(锰)茶IL-DLLMEFAAS1,3-二丁基咪唑六氟磷酸盐100 μL甲醇1 000 μL—0.26、1.86 μg/L96.0~106.6 95.2~108.9[54] As 3+、As 5+、有机As(砷)葡萄酒VA-IL-DLLMEOn line-ETAAS[C 8MIM][PF 6] 40 mg甲醇100 μL465 ng/L 98.1~104.0 96.3~104.0 96.0~102.0 [51] Co(钴)、Ni(镍)水样、食品IL-DLLMESpectrophotometer[C 6MIM][Tf 2N] 65 mg乙醇500 μL—0.65、0.32 ng/mL93.3~103.86 99.1~103.9[55] Zn 2+(锌)水样、食品IL-CIA-DLLMEFAAS[C 6MIM][PF 6] 95 mg乙醇650 μL600.18 μg/L90.3~102.2 91.2~98.5[56] Cu(铜)水样、食品 in situ-IL-ISFMESFIS1-己基-3-甲基咪唑四氟硼酸盐35 mg[Na][PF 6] 0.5 mL250.024 μg/L92.8~102.9 95.6~102.5[49] Cr 6+盐水、食品添加剂IL-DLLMEFAAS[C 6MIM][PF 6] 70 mg—1620.16 μg/L—[57] Fe(铁)水、岩石、人类血清IL-DLLMEFAAS[C 6MIM][PF 6] 100 μL乙醇1 000 μL152.4 ng/L94.0~98.0[58] Pb(铅)、Cd(镉)水样、塑料玩具 in situ-IL-DLLMEETAAS1-辛基-3-甲基咪唑氯100 μL[Li][NTf 2] 100 μL2800.2~3、10 ng/L96.0~105.0[50]无机Co营养补充剂IL-DLLMEETAAS[C 6MIM][PF 6] 80 mg甲醇—5.4 ng/L>90[59]

近年来,IL-DLLME技术也逐渐应用于复杂基质中元素的检测。Zeeb等 [49]采用原位离子液体溶剂形成微萃取(in situ ionic liquid-solvent formation microextraction,IL-ISFME)结合停流注射荧光分光光度计(stoppedflow injection spectrofluorimetry,SFI S)检测水样、食品中Cu元素,以离子液体[C 6MIM][BF 4]为萃取剂,[Na][PF 6]为阴离子交换剂,在优化条件下富集倍数为25,检出限为0.024 μg/L,回收率分别为92.8%~102.9%和95.6%~102.5%。López-García等 [50]以1-辛基-3-甲基咪唑氯([C 8MIM][Cl])作为萃取剂,应用原位IL-DLLME与ETAAS联用技术测定水样和塑料玩具中Pb和Cr元素,富集倍数高达280,检出限分别为0.2~3 ng/L和10 ng/L,回收率为96%~105%。该方法操作简单、灵敏度高、绿色环保,完全满足样品中Pb和Cr元素的检测要求。

Escudero等 [51]改进了VA-IL-DLLME技术,并首次应用于葡萄酒中不同形态As的在线检测,以离子液体[C 8MIM][PF 6]为萃取剂,甲醇为分散剂,二乙基二氨基硫代甲酸酯(diethyldithiocarbamate,DDTC)为螯合剂。在加入萃取剂和分散剂后,通过流动注射系统进行离子液体相的保留和分析物的预浓缩。该系统以一定流速驱动含有目标物的离子液体,使其留在含有填料的柱子中,然后用甲醇溶液将保留的离子液体相洗脱,最后将洗脱相泵入ETAAS的石墨管进行检测。在优化条件下回收率可达96%~104%。在线保留、分离离子液体富集相极大地缩短目标物预浓缩速度,减少样品消耗并且避免不同批次处理造成的样品污染。

2.5 IL-DLLME在其他污染物检测中的应用

Yao Cong等 [60]最早提出应用in situ-IL-DLLME检测水样中芳香化合物,在10 mL样品溶液中,注入38 μL 1-丁 基-3-甲基咪唑氯([C 4MIM][Cl]),轻微振荡后加入471 μL二(三氟甲磺酰)亚胺锂([Li][NTf 2]),形成乳浊液后振荡离心,去除上清液,取10 μL离子液体沉淀相 上高效液相色谱仪进行分析。该方法检出限为0.02~0.3 μg/L,加标回收率为84%~115%。同时,研究人员还将该方法同传统DLLME、IL-DLLME、TCA-IL-DLLME对比,结果表明该方法的富集倍数显著高于其他方法,可能因为阴离子交换剂的加入使新形成的离子液体分散成更小的液滴,增 大与目标物的接触面积,提高萃取效率。

2012年,Germán-Hernández等 [61]首次提出以离子液体作为表面活性剂用于预浓缩,该研究以1-十六烷基-3-甲基咪唑溴([C 16C 4IM][Br])为萃取剂,[Li][NTf 2]为分散剂,采用原位IL-DLLME结合HPLC-UV-FD检测烘烤谷物类食品中16 种多环芳烃(polycyclic aromatic hydrocarbons,PAHs),在优化条件下检出限为0.03~83 μg/kg,回收率为68.4%~122%。该方法无需借助有机溶剂及外界能量(微波或超声波辅助)即可萃取固体样品中的有机物,更加高效、环保。

表5IL-DLLME在其他污染物检测中的应用

Table5Application of IL-DLLME in the analysis of other contaminants

分析物(种类)样品前处理方法仪器方法萃取剂-亲水性IL分散剂-阴离子交换剂富集倍数检出限回收率/%参考文献抗菌剂(2)水样 IL-DLLMEHPLC-ESI-MS/MS[C 8MIM][PF 6] 50 μL甲醇50 μL—0.23~0.35 μg/L88.0~111.0[64]新型污染物(14)水样in situ- IL-DLLME IL-DLLMEHPLC-UV 1-丁基-3-甲基咪唑氯40 μL HNH 2MPL- FAP 30 μL [BMIM][NTf 2] 75 μL [Li][NTf 2]甲醇0.5 mL—55.1 μg/L 0.1~55.8 μg/L91~110[63]芳香胺水样UA- IL-DLLMEHPLC-UV[C 4MIM][PF 6] 100 μL甲醇750 μL>500.023、0.015、0.026 ng/mL82.0~94.0[65]若丹明B水样纺织品等IL-DLLMEFO-LADS[C 6MIM][PF 6] 75 mg乙醇500 μL—1.05 μg/L100~104.6[66]酚类(4)化妆品IL-DLLMECE-UV[C 8MIM][PF 6] 80 μL丙酮900 μL50~715~100 μg/L81.6~119.4[67]内分泌干扰酚(6)海水、工业废水in situ-IL-DLLMEHPLC-DAD[C 4MIM][Cl] 38 μL[Li][NTf 2] 340 μL140~9890.8~4.8 μg/L90.2[68]芳香混合物水样in situ-IL-DLLMEHPLC-UV[C 4MIM][Cl] 38 μL[Li][NTf 2] 471 μL—0.02~0.3 μg/L84.0~115.0[60]多环芳烃(16)烘烤谷类食品in situ-IL-DLLMEHPLC-UV-FD1-十六烷基-3-甲基咪唑溴0.06 mmol[Li][NTf 2] 34 μL6.9~140.03~83 μg/kg68.4~122.0[61]甲醛空气、水、土壤IL-DLLMEHPLC-VWD[C 8MIM][PF 6] 80 μL甲醇140 μL3550.01~0.09 ng/mL71.6~103.5 76.8~102.7[62]

IL-DLLME同样可用于检测气体污染物。Peng Bing等 [62]首次提出应用IL-DLLME结合HPLC-VWD同时检测3 种不同样品(空气、水样、土壤)中甲醛含量。固体样品需先经过溶剂提取,以离子液体[C 8MIM][PF 6]为萃取剂,甲醇为分散剂进行前处理;方法富集倍数高达355,检出限为0.01~0.09 ng/mL,回收率为71.6%~103.5%。同其他前处理方法相比,该方法具有线性范围广、检出限低、灵敏度高等特点。

近年来,一些新型污染物引起了政府和大众的关注,尽管没有被列入常规污染物名单,但对人类及环境安全造成潜在威胁。Yao Cong等 [63]分别采用传统IL-DLLME和原位IL-DLLME两种前处理方法结合HPLC-UV检测水样中14 种新型污染物,前者以1-(6-氨基-己基)-1-甲基吡咯三羟甲基氨基甲烷(五氟碘乙烷)三氟磷酸(HNH 2MPL-FAP)为萃取剂,甲醇为分散剂,后者以[C 4MIM][Cl]为萃取剂,[Li][NTf 2]为分散剂,优化条件下检出限为0.1~55.8 μg/L,回收率为91%~110%。研究人员比较两种方法,发现[C 4MIM][Cl]适合不含氨基的极性或酸性混合物的检测,获得较高的富集倍数,但其用量要高于HNH 2MPL-FAP。表5列出了IL-DLLME在一些新型污染物检测中的应用报道。

同传统有机溶剂相比,由于离子液体固有的低蒸汽压、良好的热稳定性、可调的理化性质等优点,离子液体-分散液液微萃取技术已经被广泛应用于有机化合物和金属元素的分析检测 [69]。目前,IL-DLLME仍存在一定局限性:1)离子液体较传统有机溶剂成本高,最终形成的沉淀相黏度较大,定量效果不及有机试剂,并且常用种类较少,多为咪唑类离子液体,有时需借助辅助条件如超声波、微波等方式,导致步骤和成本增加 [70];2)IL-DLLME普遍使用有一定毒性的有机溶剂作为分散剂,在降低萃取效率的同时,可能对环境及人体健康造

成威胁;3)有关不同IL-DLLME模式的萃取机理及过程优化研究较少;4)目前主要应用于简单基质,因为DLLME主要在液体介质中完成萃取,复杂基质样品会产生严重的基质效应;5)由于离子液体蒸汽压低,黏度大等特点,导致与各种仪器联用的检测方法较传统DLLME少,如与气相色谱(gas chromatography,GC)兼容性差。由此,为推广应用IL-DLLME技术,今后应加强以下方面的研发:1)针对目标物质的理化性质,研发新型廉价、适用性更广、毒性小、可生物降解的环境友好型的离子液体;2)对各种IL-DLLME模式进行对比,研究不同模式下针对不同目标物的萃取机理,优化萃取过程条件及技术参数,如应用集萃取、螯合于一体的试剂检测金属元素,将离子液体表面活性剂和磁性纳米粒子结合使用,简化操作步骤,提高萃取效率;3)强化与其他前处理技术的联用,比如QuEChERS、凝胶渗透色谱(gel permeation chromatography,GPC)、超临界流体萃取(supercritical fl uid extraction,SFE)和固相萃取(SPE)等技术,推广到各种复杂基质的应用上;4)开发新型在线DLLME技术,加强同其他检测器和仪器的联用,如质谱检测器(mass spectrometry,MS)和荧光检测器(fl uorescence detector,FLD)、气相色谱仪(GC)和毛细管电泳(capillary electrophoresis,CE)等 [71]。总之,随着研究的深入,IL-DLLME技术在食品和环境污染物等检测上的应用会更加自动化、微型化、兼容化、绿色化。

参考文献:

[1] REZAEE M,ASSADI Y,MILANI HOSSEINI M R,et al.Determination of organic compounds in water using dispersive liquidliquid microextraction[J].Journal of Chromatography A,2006,1116(1):1-9.

[2] ZHOU Qingxiang,BAI Huahua,XIE Guohong,et al.Trace determination of organophosphorus pesticides in environmental samples by temperaturecontrolled ionic liquid dispersive liquid-phase microextraction[J].Journal of Chromatography A,2008,1188(2):148-153.

[3] BAGHDADI M,SHEMIRANI F.Cold-induced aggregation microextraction:a novel sample preparation technique based on ionic liquids[J].Analytica Chimica Acta,2008,613(1):56-63.

[4] ZHANG Panjie,HU Lu,LU Runhua,et al.Application of ionic liquids for liquid-liquid microextraction[J].Analytical Methods,2013,5(20):5376-5385.

[5] WELLS A S,COOMBE V T.On the freshwater ecotoxicity and biodegradation properties of some common ionic liquids[J].Organic Process Research&Development,2006,10(4):794-798.

[6] VENTURA S P M,GON☒ALVES A M M,SINTRA T,et al.Designing ionic liquids:the chemical structure role in the toxicity[J].Ecotoxicology,2013,22(1):1-12.

[7] ZHAO Dongbin,LIAO Yongcheng,ZHANG Ziding.Toxicity of ionic liquids[J].CLEAN-Soil,Air,Water,2007,35(1):42-48.

[8] LIU Rui,LIU Jingfu,YIN Yongguang,et al.Ionic liquids in sample preparation[J].Analytical and Bioanalytical Chemistry,2009,393(3):871-883.

[9] ANDERSON J L,ARMSTRONG D W,WEI G T.Ionic liquids in analytical chemistry[J].Analytical Chemistry,2006,78(9):2892-2902.

[10] YIANTZI E,PSILLAKIS E,TYROVOLA K,et al.Vortex-assisted liquid-liquid microextraction of octylphenol,nonylphenol and bisphenol-A[J].Talanta,2010,80(5):2057-2062.

[11] KOC☒ROV☒L,BALOGH I S,☒ANDREJOV☒J,et al.Recent advances in dispersive liquid-liquid microextraction using organic solvents lighter than water.A review[J].Microchemical Journal,2012, 102:11-17.

[12] NUHU A A,BASHEER C,SAAD B.Liquid-phase and dispersive liquid-liquid microextraction techniques with de rivatization:recent applications in bioanalysis[J].Journal of Chromatography B,2011,879(17):1180-1188.

[13] TRUJILLO-RODR☒GUEZ M J,ROC☒O-BAUTISTA P,PINO V,et al.Ionic liquids in dispersive liquid-liquid microextraction[J].TrAC Trends in Analytical Chemistry,2013,51:87-106.

[14] ZHANG Jiaheng,GAO Haixiang,PENG Bing,et al.Comparison of the performance of conventional,temperature-controlled,and ultrasound-assisted ionic liquid dispersive liquid-liquid microextraction combined with high-performance liquid chromatography in analyzing pyrethroid pesticides in honey samples[J].Journal of Chromatography A,2011,1218(38):6621-6629.

[15] ZHAO Rusong,WANG Xia,LI Fuwei,et al.Ionic liquid/ionic liquid dispersive liquid-liquid microextraction[J].Journal of Separation Science,2011,34(7):830-836.

[16] RAVELO-P☒REZ L M,HERN☒NDEZ-BORGES J,ASENSIORAMOS M,et al.Ionic liquid based dispersive liquid-liquid microextraction for the extraction of pesticides from bananas[J].Journal of Chromatography A,2009,1216(43):7336-7345.

[17] ZHANG Li jin,CHEN Fang,LIU Shaowen,et al.Ionic liquidbased vortex-assisted dispersive liquid-liquid microextraction of organophosphorus pesticides in apple and pear[J].Journal of Separation Science,2012,35(18):2514-2519.

[18] LIN P C,TSENG M C,SU A K,et al.Functionalized magnetic nanoparticles for small-molecule isolation,identification,and quantifica tion[J].Analytical Chemistry,2007,79(9):3401-3408.

[19] ZHANG Jiaheng,LI Min,YANG Miyi,et al.Magnetic retrieval of ionic liquids:fast dispersive liquid-liquid microextraction for the determination of benzoylurea insecticides in environmental water samples[J].Journal of Chromatography A,2012,1254:23-29.

[20] QIN Hui,LI Bi,LIU Mousheng,et al.Separation and preconcentration of glucocorticoids in water samples by ionic liquid supported vortex-assisted synergic microextraction and HPLC determination[J].Journal of Separation Science,2013,36(8):1463-1469.

[21] XU Xu,LIU Zhuang,ZHAO Xin,et al.Ionic liquid-based microwaveassisted surfactant-improved dispersive liquid-liquid microextraction and derivatization of aminoglycosides in milk samples[J].Journal of Separation Science,2013,36(3):585-592.

[22] YU Chen,ZHANG Sanbing,ZhANG Jiaheng,et al.An in situ ionic liquid dispersive liquid-liquid microextraction method for the detection of pyrethroids by LC-UV in environmental water samples[J].Journal of the Brazilian Chemical Society,2013,24(6):1034-1040.

[23] WANG Xia,XU Qingcai,CHENG Chuange,et al.Rapid determination of DDT and its metabolites in environmental water samples with mixed ionic liquids dispersive liquid-liquid microextraction prior to HPLC-UV[J].Chromatographia,2012,75(17/18):1081-1085.

[24] LIU Yu,ZHAO Ercheng,ZHU Wentao,et al.Determination of four heterocyclic insecticides by ionic liquid dispersive liquid-liquid microextraction in water samples[J].Journal of Chromatography A,2009,1216(6):885-891.

[25] ZHANG Jiaheng,LIANG Zhe,LI Songqing,et al. in-situ metathesis reaction combined with ultrasound-assisted ionic liquid dispersive liquid-liquid microextraction method for the determination of phenylurea pesticides in water samples[J].Talanta,2012,98:145-151.

[26] LI Songqing,GAO Haix iang,ZhANG Jiaheng,et al.Determination of insecticides in water using in situ halide exchange reaction-assisted ionic liquid dispersive liquid-liquid microextraction followed by highperformance liquid chromatography[J].Journal of Separation Scien ce,2011,34(22):3178-3185.

[27] ZHONG Qiu,SU Ping,ZHANG Yao,et al. in-situ ionic liquid-based microwave-assisted dispersive liquid-liquid microextraction of triazine herbicides[J].Microchimica Acta,2012,178(3/4):341-347.

[28] HE Lijun,LUO Xianli,JIANG Xiuming,et al.A new1,3-dibutylimidazolium hexafluorophosphate ionic liquidbased dispersive liquid-liquid microextraction to determine organophosphorus pesticides in water and fruit samples by highperformance liquid chromatography[J].J ournal of Chromatography A,2010,1217(31):5013-5020.

[29] WANG Suli,REN Liping,XU Yanjun,et al.Application of ultrasound-assisted ionic liquid dispersive liquid-phase microextraction followed high-performance liquid chromatography for the determination of fungicides in red wine[J].Microc himica Acta,2011,173(3/4):453-457.

[30] RAVELO-P☒REZ L M,HERN☒NDEZ-BORGES J,HERRERAHERRERA A V,et al.Pesticide extraction from table grapes and plums using ionic liquid based dispersive liquid-liquid microextraction[J].Analytical and Bioanalytical Chemistry,2009,395(7):2387-2395.

[31] DONG Sheying,HU Qing,YANG Zhen,et al.An ionic liquid-based ultrasound assisted dispersive liquid-liquid microextraction procedure followed by HPLC for the determination of low concentration of phytocides in soil[J].Microchemical Journal,2013,110:221-226.

[32] 董社英,胡清,李靖,等.离子液体微波辅助液相萃取-高效液相色谱法同时测定土壤中5种微量有机氧农药[J].分析试验室,2013,32(8):48-52.

[33] HOU Dekun,GUAN Yan,DI Xiaowei.Temperature-induced ionic liquids dispersive liquid-liquid microextraction of tetracycline antibiotics in environmental water samples assisted by complexa tion[J].Chromatographia,2011,73(11/12):1057-1064.

[34] 侯德坤,关燕,狄晓威.温度驱动离子液体分散微萃取/超高压液相色谱检测水样中的微量四环素[J].分析测试学报,2011,30(3):259-263.

[35] V☒ZQUEZ M M,V☒ZQUEZ P P,GALERA M M,et al.Determination of eight fluoroquinolones in gr oundwater samples with ultrasound-assisted ionic liquid dispersive liquid-liquid microextraction prior to high-performance liquid chromatography and fluorescence detection[J].Analytica Chimica Acta,2012,748:20-27.

[36] GAO Shiqian,YANG Xiao,YU Wei,et al.Ultrasound-assisted ionic liquid/ionic liquid-dispersive liquid-liquid microextraction for the determination of sulfonamides in i nfant formula milk powder using highperformance liquid chromatography[J].Talanta,2012,99:875-882.

[37] ARROYO-MANZANARES N,GARC☒A-CAMPA☒A A M,G☒MIZGRACIA L.Comparison of different sample treatments for the analysis of ochratoxin A in wine by capillary HPLC with laser-induced fluorescence detection[J].Analytical and Bioanalytical Chemistry,2011,401(9):2987-2994.

[38] MOHAMMADI A,TAVAKOLI R,KAMANKESH M,et al.Enzymeassisted extraction and ionic liquid-based dispersive liquid-liquid microextraction followed by high-performance liquid chromatography for determination of patulin in apple juice and method optimization using central composite design[J].Analytica Chimica Act a,2013,804:104-110.

[39] YANG Peng,REN Haixia,QIU Hongde,et al.Determination of four trace preservatives in street food by ionic liquid-based dispersive liquidliquid micro-extraction[J].Chemical Papers,2011,65(6):747-753.

[40] GUO Jingbo,WU Hao,DU Liming,et al.Determination of brilliant blue FCF in food and cosmetic samples by ionic liquid independent disperse liquid-liquid micro-extraction[J].Analytical Methods,2013,5(16):4021-4026.

[41] WU Hao,GUO Jingbo,DU Liming,et al.A rapid shaking-based ionic liquid dispersive liquid phase microextraction for the simultaneous determination of six synthetic food colourants in soft drinks,sugar-and gelatin-based confectionery by high-performance liquid chromatography[J].Food Chemistry,2013,141(1):182-186.

[42] WANG Ruoyu,SU Ping,YANG Yi.Optimization of ionic liquidbased microwave-assisted dispersive liquid-liquid mi c roextraction for the determination of plasticizers in water by response surface methodology[J].Analytical Methods,2013,5(4):1033-1039.

[43] FAN Yingying,LIU Shuhui,XIE Qilong.Rapid determination of ph thalate esters in alcoholic beverages by conventional ionic liquid dispersive liquid-liquid microextraction coupled with high performance liquid chromatography[J].Talanta,2014,119:291-298.

[44] HO Y M,TSOI Y K,LEUNG K S Y.Ionic-liquid-based dispersive liquid-liquid microextraction for high-throughput multiple food contaminant screening[J].Journal of Separation Science,2013,36(23):3791-3798.

[45] GHAREHBAGHI M,SHEMIRANI F.A novel method for dye removal:ionic liquid-based dispersive liquid-liquid extraction(ILDLLE)[J].CL EAN-Soil,Air,Water,2012,40(3):290-297.

[46] 郭京波,吴昊,王婕艳,等.离子液体自分散液-液微萃取测定食品中的柠檬黄与亮蓝[J].分析测试学报,2012,31(12):1499-1504.

[47] L☒PEZ-GARC☒A I,VICENTE-MART☒NEZ Y,HERN☒NDEZC☒RDOBA M.Determination of very low amounts of chromium(Ⅲ)and(Ⅵ)using dispersive liqu id-liquid microextraction by in situ formation of an ionic liquid followed by electrothermal atomic absorption spectrometry[J].Journal of Analytical Atomic Spectrometry,2012,27(5):874-880.

[48] ABSALAN G,AKHOND M,SHEIKHIAN L,et al.Temperaturecon trolled ionic liquid-based dispersive liquid-phase microextraction,preconcentration and quantification of nano-amounts of silver ion by using disulfiram as complexing agent[J].Analytical Methods,2011,3(10):2354-2359.

[49] ZEEB M,GANJALI M R,NOROUZI P,et al.Separation and preconcentration system based on microextraction with ionic liquid for determination of copper in water and food samples by stopped-flow injection spectrofluorimetry[J].Food and Chemical Toxicology,2011,49(5):1086-1091.

[50] L☒PEZ-GARC☒A I,VICENTE-MART☒NEZ Y,HERN☒NDEZC☒RDOBA M.Determination of lead and cadmium using an ionic liquid and dispersive liquid-liquid microextraction followed by electrothermal atomic absorption spectrometry[J].Talanta,2013,110:46-52.

[51] ESCUDERO L B,MARTINIS E M,OLSINA R A,et al.Arsenic spec iation analysis in mono-varietal wines by on-line ionic liquidbased dispersive liquid-liquid microextraction[J].Food Chemistry,2013,138(1):484-490.

[52] MOLAAKBARI E,MOSTAFAVI A,AFZALI D.Ionic liquid ultrasound assisted dispersive liquid-liquid microextraction method for preconcentration of trace amounts of rhodium prior to flame atomic absorption spectrometry determination[J].Journal of Hazardous Materials,2011,185(2):647-652.

[53] ESKANDARI H. in situ formed1-hexyl-3-methylimidazolium hexafluorophosphate for dispersive liquid-liquid microextraction of Pd(Ⅱ)prior to electrothermal AAS and spectrophotometry[J].Turkish Journal of Chemistry,2012,36(4):631-643.

[54] WEN Shengping,ZHU Xiashi.Speciation analysis of Mn(Ⅱ)/ Mn(Ⅶ)in tea samples using flame atomic absorption spectrometry after room temperature ionic liquid-based dispersive liquid-liquid microextraction[J].Food Analytical Methods,2014,7(2):291-297.

[55] KHANI R,SHEMIRANI F.Simultaneous determination of trace amounts of cobalt and nickel in water and food samples using a combination of partial least squares method and dispersive liquidliquid microextraction based on ionic liquid[J].Food Analytical Methods,2013,6(2):386-394.

[56] ZEEB M,SADEGHI M.Modified ionic liquid cold-induced aggregation dispersive liquid-liquid microextraction followed by atomic absorption spectrometry for trace determination of zinc in water and food samples[J].Microchimica Acta,2011,175(1/2):159-165.

[57] TAZIKI M,SHEMIRANI F,MAJIDI B.Robust ionic liquid-based dispersive liquid-liquid microextraction m ethod for determination of chromium(Ⅵ)in saline solutions[J].Communications in Soil Science and Plant Analysis,2013,44(22):3400-3411.

[58] KHAYATIAN G,HOSSEINI S S,HASSANPOOR S.Ionic liquidbased dispersive liquid-liquid microextraction for determin ation of trace amounts of iron in water,rock and human blood serum samples[J].Journal of the Iranian Chemical Society,2013,10(6):1167-1173.

[59] BERTON P,MARTINIS E M,MARTINEZ L D,et al.Selective determination of inorganic cobalt in nutritional supplements by ultrasound-assis ted temperature-controlled ionic liquid dispersive liquid phase microextraction and electrothermal atomic absorption spectrometry[J].Analytica Chimica Acta,2012,713:56-62.

[60] YAO Cong,ANDERSON J L.Dispersive liquid-liquid microextraction using an in situ metathesis reaction to form an ionic liquid extraction phase for the preconcentration of aromatic compounds from water[J].Analytical and Bioanalytical Chemistry,2009,395(5):1491-1502.

[61] GERM☒N-HERN☒NDEZ M,PINO V,ANDERSON J L,et al.A novel in situ preconcentration method with ionic liquid-based surfactants resulting in enhanced sensitivity for the extraction of polycyclic aromatic hydrocarbons from toasted cereals[J].Journal of Chromatography A,2012,1227:29-37.

[62] PENG Bing,ZHANG Jiaheng,WU Chenghao,et al.Use of ionic liquid-based dispersive liquid-liquid microextraction and highperformance liquid chromatography to detect formaldehyde in air,water,and soil samples[J].Journal of Liquid Chromatography&Related Technologies,2014,37(6):815-828.

[63] YAO Cong,LI Tianhao,TWU P,et al.Selective extraction of emerging contaminants from water samples by dispersive liquidliquid microextraction using functionalized ionic liquids[J].Journal of Chromatography A,2011,1218(12):1556-1566.

[64] ZHAO Rusong,WANG Xia,SUN Jing,et al.Determinati on of triclosan and triclocarban in environmental water samples with ionic liquid/ionic liquid dispersive liquid-liquid microextraction prior to HPLC-ESI-MS/MS[J].Microchimica Acta,2011,174(1/2):145-151.

[65] HAN Dandan,YAN Hongyuan,ROW K H.Ionic liquid-based dispersive liquid-liquid microextraction for sensitive determination of a romatic amines in environmental water[J].Journal of Separation Science,2011,34(10):1184-1189.

[66] TAZIKI M,SHEMIRANI F,MAJIDI B.Robust ionic liquid against high concentration of salt for preconcentration and determination of rhodamine B[J].Separation and Purification Technology, 2012,97:216-220.

[67] ZHOU Caihong,TONG Shanshan,CHANG Yunxia,et al.Ionic liquid-based dispersive liquid-liquid microextraction with backextraction coupled with capillary electrophoresis to determine phenolic compounds[J].Electrophoresis,2012,33(8):1331-1338.

[68] L☒PEZ-DARIAS J,PINO V,AYALA J H,et al.in-situ ionic liquid-dispersive liquid-liquid microextraction method to determine endocrine disrupting phenols in seawaters and industrial effluents[J].Microchimica Acta,2011,174(3/4):213-222.

[69] MART☒N-CALERO A,PINO V,AFONSO A M.Ionic liquids as a tool for determination of metals and organic compounds in food analysis[J].TrAC Trends in Analytical Chemistry,2011,30(10):1598-1619.

[70] ANDRUCH V,BALOGH I S,KOC☒ROV☒L,et al.Five years of dispersive liquid-liquid microextraction[J].Applied Spectroscopy Reviews,2013,48(3):161-259.

[71] SARAJI M,MALIHE K B.Recent developments in dispersive liquidliquid microextraction[J].A nalytical and Bioanalytical Chemistry,2014,406:2027-2066.

Application of Ionic Liquid-Dispersive Liquid-Liquid Microextraction for the Determination of Contaminants in Foods and Environment:A Review

ZHANG Yan

1,2,3,4,5,ZHANG Yaohai

2,3,4,5,JIAO Bining

1,2,3,4,5,*

(1.College of Horticulture and Landscape Architecture,Southwest University,Chongqing400715,China;2.National Citrus Engineering Research Center,Citrus Research Institute,Chinese Academy of Agricu ltural Sciences,Chongqing400712,China;3.Laboratory of Quality and Safty Risk Assessment for Citrus Products,Ministry of Agriculture,Chongqing400712,China;4.Quality Supervision and Testing Centre for Citrus and Seedling,Ministry of Agriculture,Chongqing400712,China;5.Chongqing Key Laboratory of Citrus Science,Chongqing400712,China)

Abstract:Ionic liquid(IL)have gained extensive applications in the fields of extraction and separation due to their unique properties,such as low vapor pressure,high thermal stability,good solubility and designable structures.In the paper,the characteristics of IL and the modes of ionic liquid-dispersive liquid-liquid microextraction are introduced.The recent applications of this technique in the determination of contaminants in foods and the environment are emphatically reviewed.Based on the above discussion,future exploration and development of this technique are also proposed.

Key words:ionic liquid(IL);dispersive liquid-liquid microextraction(DLLME);food;environment pollutant;application

中图分类号:O658.2

文献标志码:A

文章编号:1002-6630(2015)05-0250-10

doi:10.7506/spkx1002-6630-201505046

收稿日期:2014-03-21

基金项目:国家现代农业(柑桔)产业技术体系建设专项(CARS-27);2014年国家农产品质量安全风险评估重大专项(GJFP2014003);重庆市自然科学基金重点项目(cstc2013jjB80009)

作者简介:张琰(1988—),女,硕士研究生,研究方向为果品营养与质量安全。E-mail:feiyangzy810@163.com

*通信作者:焦必宁(1964—),男,研究员,本科,研究方向为果蔬贮藏加工技术与质量安全。E-mail:bljiao@tom.com